-

Get a Solution For

All Hydraulic Clampings DevicesWe are team of the professionals -

Get a Solution For

All Hydraulic Clampings DevicesWe are team of the professionals

- Turning big ideas into great products

- +91 7720967112

Welcome to Gripart Clamping Technologies

As the technology is advancing towards all sector of industry tolerances which were dream before have come into reality clamping technology needs to be maximum precise and reliable in manufacturing and inspection to support it Hydraulic expanding work and tool holdings are one of the most reliable precision and high performance tools that are used today by leading automobile industries. Armed with a team of young and dynamic professionals including highly qualified engineers, skilled designers, researcherd and quality controllers, Tech precision clampings is a name to reckon with established in the year 2012 our company has great reputation as specialized manufacturer with the commitment to gain 100%.

Customer satisfaction , we offer Hydraulic tool holder, Hydraulic lock nuts, Hydraulic mandrels,collete type expanding mandrels, collets,Arbors, VMC & HMC Hydraulic Fixtures and Indexable Tool Holder etc. We are also engaged in taking up all kinds of job works hydraulic tool holder, Hydraulic lock nut and Hydraulic Expanding Mandrels.

we are able to deliver the most precise and efficient range of products to customers. Owing to our commitment to quality and professional approach, We are highly respected and trusted by our global clients.

Quality Assurance

Having uncompromising approach towards the quality of products, we keep in mind that best quality is the only factor that can satisfy customers efficiently to ensure the high standard of quality , we source premium grade raw material from reliable vendors only. We also test it at our premises before sending to the manufacturing unit .The complete manufacturing process is carried out under the vigil eye of quality controllers,finally,each fine-finished piece is rigorously tested by expert quality analysts.

The facilities are also upgraded from time to time at par with latest trends and our manufacturing requirements, which enables us to keep pace with constant changing market demands.

Our Products

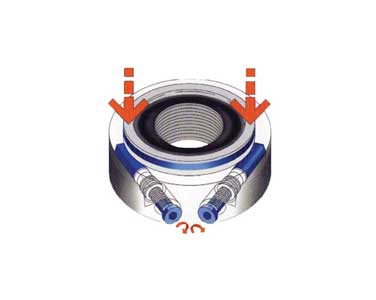

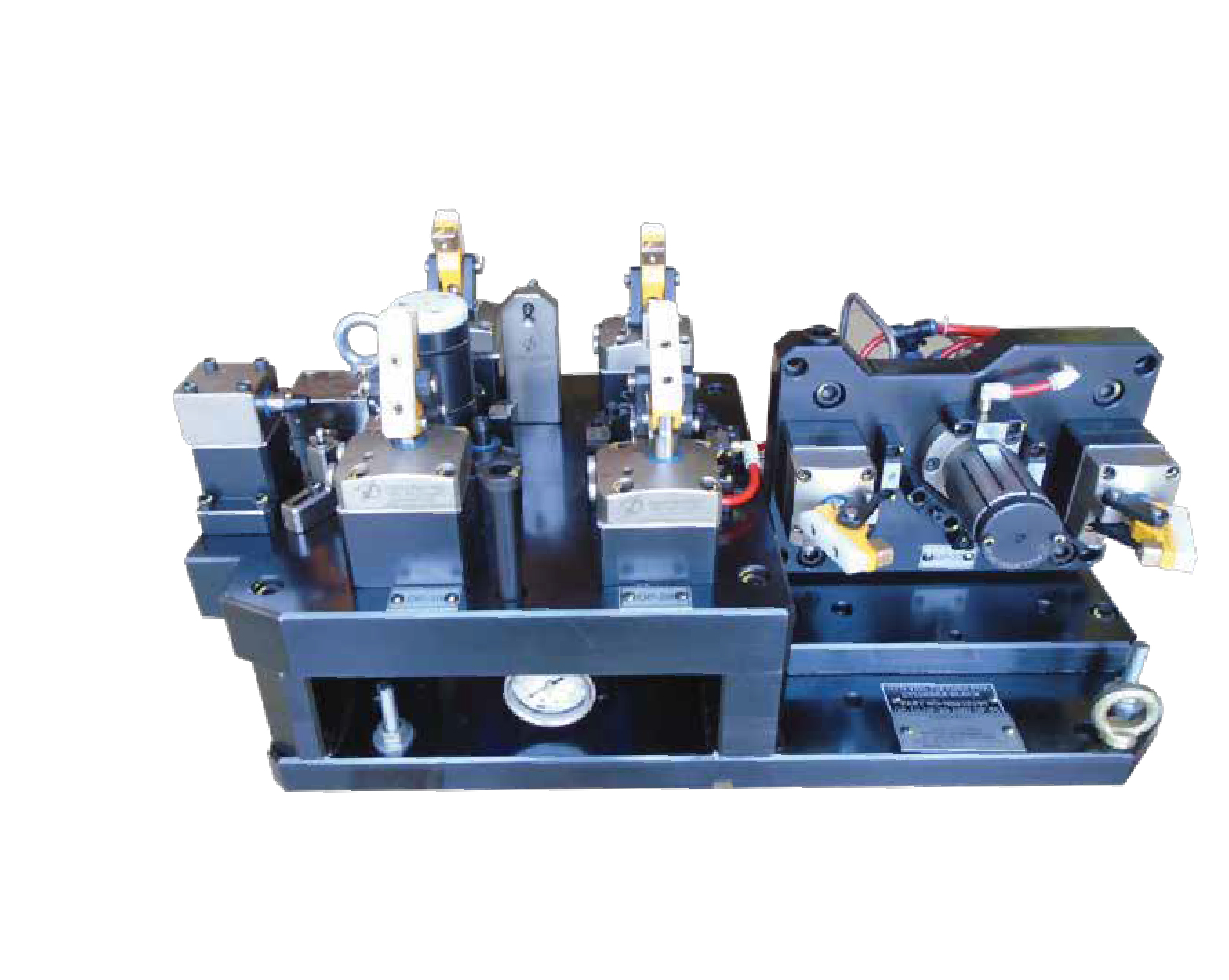

Hydraulic Expanding Mandrels

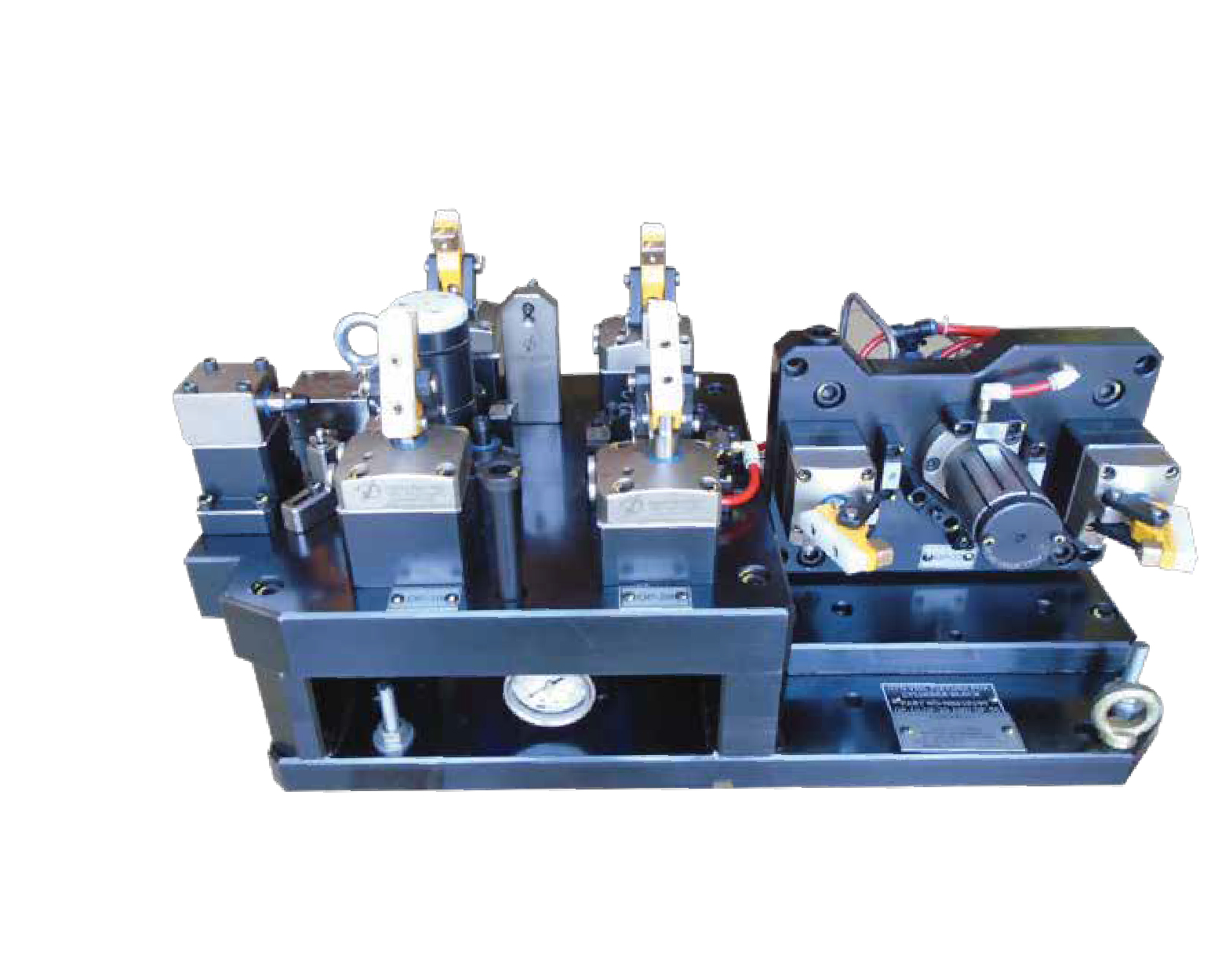

Collet Type Hobbing Fixture

Gear Shaving Fixture (Machine Mounted)

Gear Shaving Fixture (Between Center Type)

Hydraulic Gear Grinding Fixture

Collet Type Gear Grinding Fixture

Hydraulic Inspection Mandrels

Hydraulic Turning Mandrels

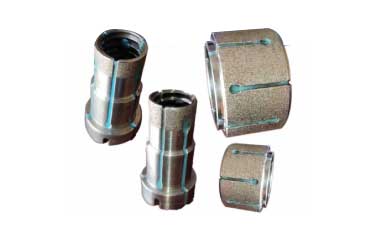

Hydraulic Lock Nut

CNC Hobbing machine Arbors

Threaded Clamping System

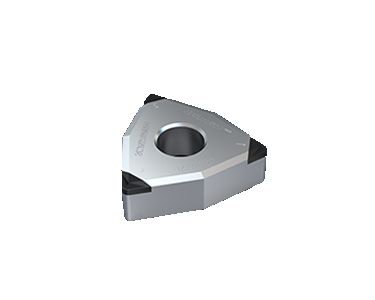

Collet

Friction Coating

Our Services

We Offer Repairing Service For The The Given Products

Our Gallery

Our Awesome Clients

Contact Us

-

birajdar@gripartclampingtechnologies.com sales@gripartclampingtechnologies.com

hr@gripartclampingtechnologies.com

- +91 7720967112

- GRIPART CLAMPING TECHNOLOGIES Gat. No. 1065(P), Casa Rioc 2, Flat No: 407, Chikhali, Pune- 412 114.